Comprehensive Aluminum Casting Capabilities for Custom Industrial Components

Comprehensive aluminum casting services provide businesses the ability to create custom industrial parts tailored to their specific requirements. These services employ advanced processes such as sand casting, die casting, and investment casting. The resulting components are lightweight, durable, and resistant to corrosion, making them appropriate for numerous industries. Understanding the benefits and applications of these casting processes can substantially impact production efficiency and quality. What factors should one examine when picking an aluminum casting service?

The Advantages of Complete Aluminum Casting Services

Though numerous manufacturing techniques exist, full-service aluminum casting services offer a distinctive set of benefits that can considerably elevate production efficiency and product quality. This technique permits the production of intricate designs with high dimensional accuracy, lessening the need for extensive machining. The versatility of aluminum enables the creation of lightweight components without reducing strength, making it optimal for multiple applications.

Moreover, complete aluminum casting services provide a streamlined production process, cutting down lead times and reducing material waste. The capacity to produce large volumes consistently guarantees that manufacturers can meet demand without compromising quality. Additionally, aluminum's resistance to corrosion and excellent thermal conductivity contribute to the longevity and performance of the final products. On the whole, these benefits make complete aluminum casting services an attractive option for industries seeking efficiency, precision, and durability in their manufacturing processes.

Widespread Applications of Aluminum Cast Parts in Various Industries

Aluminum cast components are broadly applied across various industries due to their exceptional properties and advantages. In the automotive sector, manufacturers depend on these components for engine blocks, transmission housings, and structural frames, taking advantage of their lightweight nature and corrosion resistance. The aerospace industry also employs aluminum casting for parts like brackets and housings, which contribute to reduced weight and improved fuel efficiency.

Within the construction industry, aluminum castings are employed in window frames, door frames, and roofing materials, improving both durability and visual appeal. Additionally, the electrical industry often integrates aluminum cast parts in enclosures and heat sinks, providing superior temperature regulation.

The marine sector appreciates aluminum for its protection against saltwater corrosion, using it for components such as engine parts and boat hulls. On the whole, the versatility of aluminum cast parts makes them vital across many applications, enhancing durability and performance in diverse fields.

Important Aluminum Casting Technologies for Custom Part Production

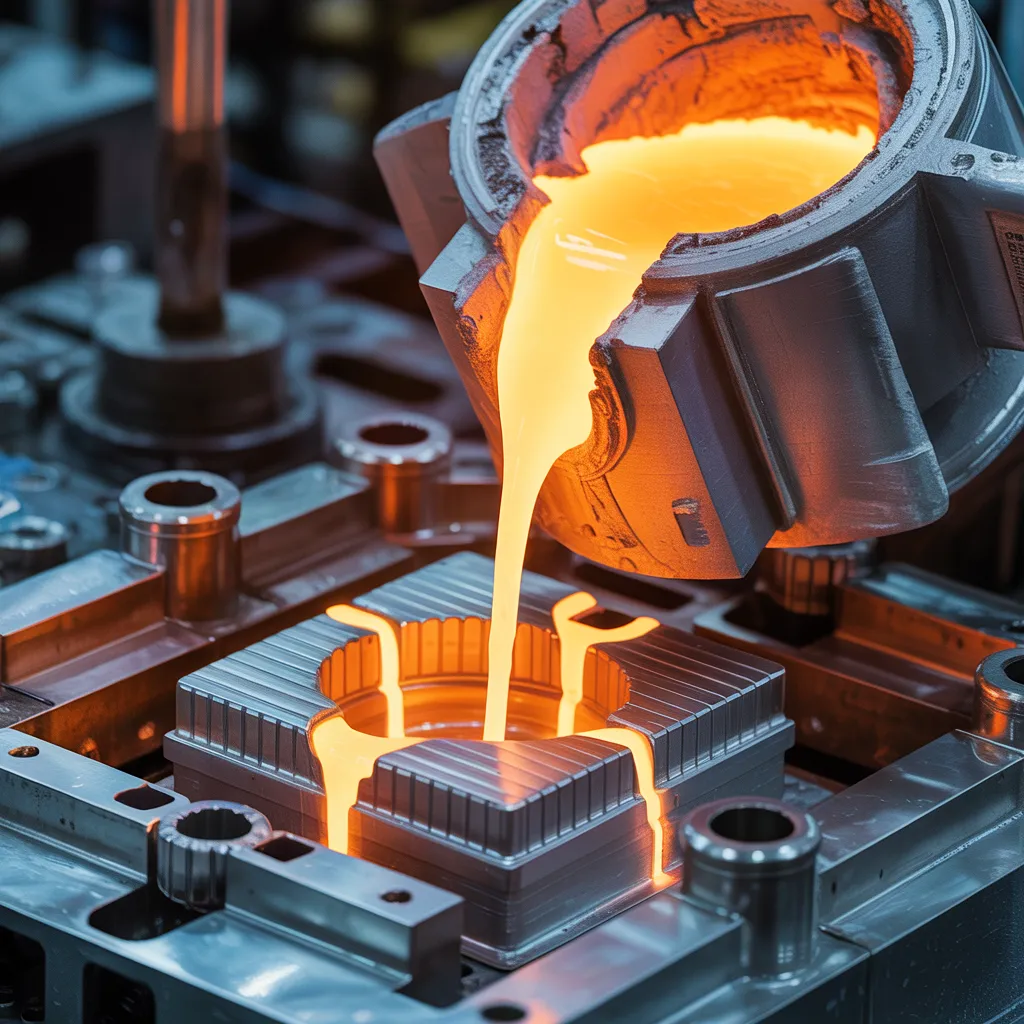

Several important techniques are implemented in aluminum casting to fabricate custom parts that satisfy specific design needs. One prevalent method is sand casting, which entails creating a mold from sand and pouring molten aluminum into it. This method is excellent for complex shapes and facilitates affordable production of small to medium-sized parts.

Another method is die casting, where molten aluminum is injected into a metal mold under high pressure. This process is ideal for high-volume production and offers excellent dimensional accuracy and surface finish.

Investment casting, or lost-wax casting, is another method that enables intricate designs and smooth finishes. This process entails producing a wax pattern that gets covered with a ceramic coating, which is subsequently heated to eliminate the wax and solidify the coating prior to introducing aluminum.

These processes collectively strengthen the versatility and performance of aluminum casting for customized industrial applications.

Selecting the Right Aluminum Casting Service?

Picking the suitable aluminum casting service can greatly affect the success of a project, particularly after understanding the different techniques offered for custom part production. Future clients should evaluate several key factors when picking a service provider. First, it is essential to take into account the company's experience and expertise in specific casting methods, such as sand casting or die casting. This guarantees the service can meet the specific requirements of the project.

In addition, customers should examine the provider's ability to handle the required volume and complexity of parts. Technological capabilities, such as advanced machinery and software for design, also play a significant role in achieving precision and efficiency.

An additional key element is the company's reputation for customer service and responsiveness, as strong communication can support more efficient project execution. Eventually, a thorough evaluation of these factors will lead to a more successful partnership and better project outcomes.

How to Achieve High Quality in Aluminum Casting

Preserving high quality in aluminum casting is vital for guaranteeing the reliability and performance of cast pieces. To achieve this, several key elements must be addressed throughout the casting process. First, selecting top-quality aluminum alloys can substantially impact the final product's strength and resistance to corrosion. Additionally, maintaining precise temperature control during melting and pouring is essential, as variations can cause defects such as helpful tips porosity or inclusions.

Executing comprehensive quality control measures, including non-destructive testing and dimensional inspections, guarantees that any issues are discovered early. In addition, using cutting-edge casting techniques, such as investment casting or die casting, can boost dimensional accuracy and surface finish. Ultimately, continuous training for personnel involved in the casting process fosters a culture of quality awareness, promoting attention to detail. By concentrating on these aspects, manufacturers can consistently deliver premium aluminum castings that meet the specific needs of their clients.

FAQ

What's the Typical Lead Time for Custom Aluminum Casting Orders?

The average lead time for custom aluminum casting orders extends from 4-8 weeks, depending on factors such as design complexity, volume, and production scheduling, which can vary considerably among diverse manufacturers and projects.

Can You Manage Small Batch Orders for Aluminum Cast Parts?

Yes, limited quantity orders for aluminum cast parts can be accommodated. The company recognizes the different needs of clients and is prepared to handle different quantities without diminishing the quality or production schedule.

Which Certifications Are Held by Your Aluminum Casting Services?

Our aluminum casting services hold multiple industry certifications, including ISO 9001 certification for quality management systems and ASTM material specification standards. These certifications guarantee adherence to strict quality and safety standards during aluminum casting operations.

Does Your Company Offer Design Support for Custom Aluminum Parts?

Yes, they offer design assistance for custom aluminum pieces. Their team engages with clients, supplying expertise in material selection, optimization methods, and CAD modeling to confirm designs satisfy specifications and manufacturing requirements successfully.

Which Post-Casting Services Are Offered for Aluminum Parts?

Post-production services for aluminum parts typically include machining, surface finishing, heat treatment, inspection, and assembly. These additional processes elevate the final product's precision, durability, and overall quality, making certain it meets specific industry standards and customer requirements.